pharm-a-spheres

With more than 40 years of experience in manufacturing and testing of pharm-a-spheres™ sugar spheres for numerous customers we guarantee the best solution for your application. Our sugar spheres are characterized by an outstanding mechanical stability for further processing. Pharm-a-spheres™ is the best carrier for your sustained-release formulation in a unique quality, based on a highly controlled and certified manufacturing process. We are dedicated to provide tailor-made solutions for our customers’ wishes.

Sugar spheres are a widely used excipient for sustained-release pellet formulations.

Pellets are a multiparticle, solid form of medication. The individual pellets are almost spherical with diameters usually between 100 and 2000 μm.

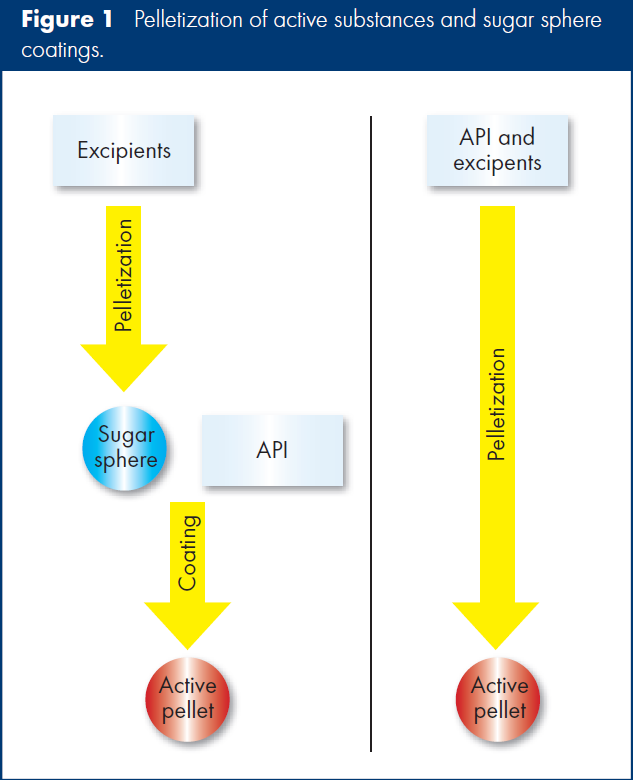

There are numerous procedures for pelletization, with two fundamentally competing concepts. On the one hand, the use of sugar spheres, which are then coated with the active substance, and on the other, direct pelletization of active substance/excipient mixtures. Figure 1 illustrates these two alternatives. ln the first option, sugar spheres (also called neutral pellets, nonpareil seeds, microgranules or sugar beads) are produced, preferably using a layered sugar-coating structure. The result is sugar spheres with sufficient mechanical stability for further processing. The ideally rounded sugar spheres classed in closely graduated particle sizes are then coated with the active substance and sustained release additives. The core of the finished pellet contains no active substance itself so that this solution is used for low-dose substances or substances with a high effect/dose relation.

But the use of small sugar spheres and corresponding procedures also makes it possible to use this method to produce pellets containing more than 75% active substance. ln the second concept, pelletization already includes the active substance itself. The procedures developed here consist of fluidized bed granulation, rotor granulation, or extrusion followed by spheronization, whereby the initially cylindrical particles are then rounded out in a second step. The advantage of this procedure is that the whole pellet contains the active substance.

There are numerous applications for both alternatives on the market, so it is still not possible to ascertain any clear preference of one over the other. Each solution offers its own pros and cons, depending on the specific product. The following points outline certain aspects where the two concepts differ, to make it easier for the user to decide which one to choose:

![Diagram of sugar spheres]() The use of sugar spheres means that the drug producer can outsource pelletization to a specialist and concentrate on processing the API. This will produce sugar spheres as a spherical excipient of uniform size.

The use of sugar spheres means that the drug producer can outsource pelletization to a specialist and concentrate on processing the API. This will produce sugar spheres as a spherical excipient of uniform size.- The shaping process involved in pelletization entails thermal load and contact with a solvent (usually water). This can cause stability problems, depending on the susceptibility of the active substance.

- Pelletization and classification produces fractions (attrition or agglomerates): recycling these in the production process often causes quality, batch homogeneity and traceability problems. lf active substances are already involved in the pelletization process, fraction disposal is often not possible for cost reasons, whereas in the case of sugar spheres, only low-cost excipients are affected.

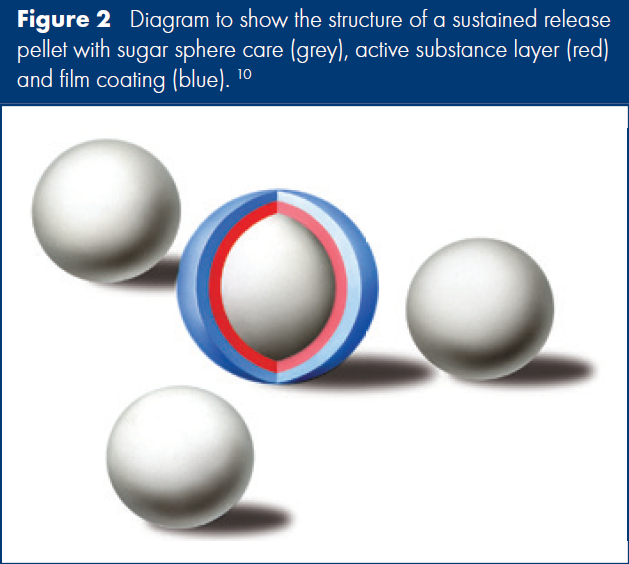

- Pellets produced by direct pelletization often only show moderate mechanical stability. But subsequent coating procedures demand adequate abrasion and crushing resistance. The use of sugar spheres results in a layered structure of the subsequent sustained release pellets, as shown in Figure 2.

Why should you decide to use pharm-a-spheres™ sugar spheres?

- High mechanical stability

- No attrition

- Low friability

- High degree of sphericity

- Non-porous surface

- Smooth surface

- Outstanding microbiological

quality - and a lot more!

PHARM-A-SPHERES

Contact

pharm-a-spheres GmbH

Hafenstraße 9

D-25436 Tornesch

Telefon: 0 41 22 / 95 76 – 0

Telefax: 0 41 22 / 95 76 – 76

EMail: [email protected]